WORKING METHOD

DBS works according to the Surinamese management system known as the CELOS management system. This system is based on the natural cycle and the ecology of the forest. The system makes it possible to utilize the maximum sustainable harvest, whilst preserving the ecologic balance of the forest. The system envelops a polycyclic, selective harvest practice that follows the principle of Reduced Impact Logging (RIL).

By regularly training our staff, we are capable to maintain our level of RIL knowledge. Information about forest resources and terrain conditions is acquired regularly by means of a 100% commercial forest inventory, while we gather long term ecological data through our Permanent Sample Plots (PSP) program. Details on the exploitation can be found in our forest exploitation plan and our annual harvesting plan.

WOOD PROCESSING

EXPLOITATION

Our exploitation operation is situated near the Nassau Mountains in the Brokopondo District. In this area, we have four forest concessions with Primary forest that have high representation of species such as Purple Heart, Basralocus (Guyana Teak), Walaba and Kopi. Our base camp on the Anjumaracreek is provided with all daily comforts. By dividing our concessions into predefined blocks, we are able to maintain a cutting cycle of 25 years and we can harvest occurring commercial timber in conjunction with the forestry service of Suriname.

A post harvesting assessment is carried out in each block that has been harvested. This means that it is inspected and then closed off for 25 years, so that the forest may recover from the impact. The inspection of blocks is done with the purpose to restore the forests’ biodiversity and ecological functions to its original state as best as possible.

Things that have our attention during these assessments are the free-flowing capability of creeks and the rehabilitation of forest log landings to avoid water logging. It is also assessed if commercially viable and selected trees have been left standing or lying in the forest. These will still have to be extracted accordingly.

SAWMILL

High-quality roundwood can be processed at our own sawmill, situated at SuHoZa. This sawmill is the only fully automated band mill in the region. We have the options to produce poles, beams and sawn wood. All our products can be shipped by tugboat and pontoons to Paramaribo from our own nearby dock, situated on the Suriname river.

REDUCED IMPACT LOGGING (RIL)

DBS strives for sustainability by following the principles of Reduced Impact Logging (RIL). By planning and projecting feeder roads, we can mitigate the adverse effects of log extraction on the forest. Further mitigation of adverse effects can be achieved by means of directional felling, where the tree is prepared to fall in a carefully planned direction. By making holes in the forest crowncover, we can even increase the level of biodiversity, because different lighting creates microclimates, with different species. With a carefully thought out policy, we can achieve and maintain this delicate balance.

GEOGRAPHIC INFORMATION SYSTEM (GIS)

DBS has a highly developed GIS department. By means of a preliminary forest inventory, it is possible to classify, select and plot each tree digitally and hardcopy on various types of maps. By using various classification criteria, we can sketch an image of the forest in 25 years time and how to optimally manage and harvest the next cycle. Our GIS department enables us to trace back any tree at any time for any product. There is 100% traceability.

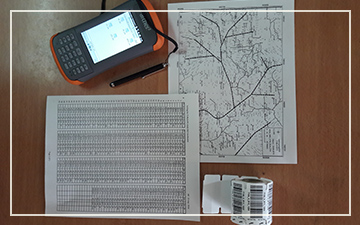

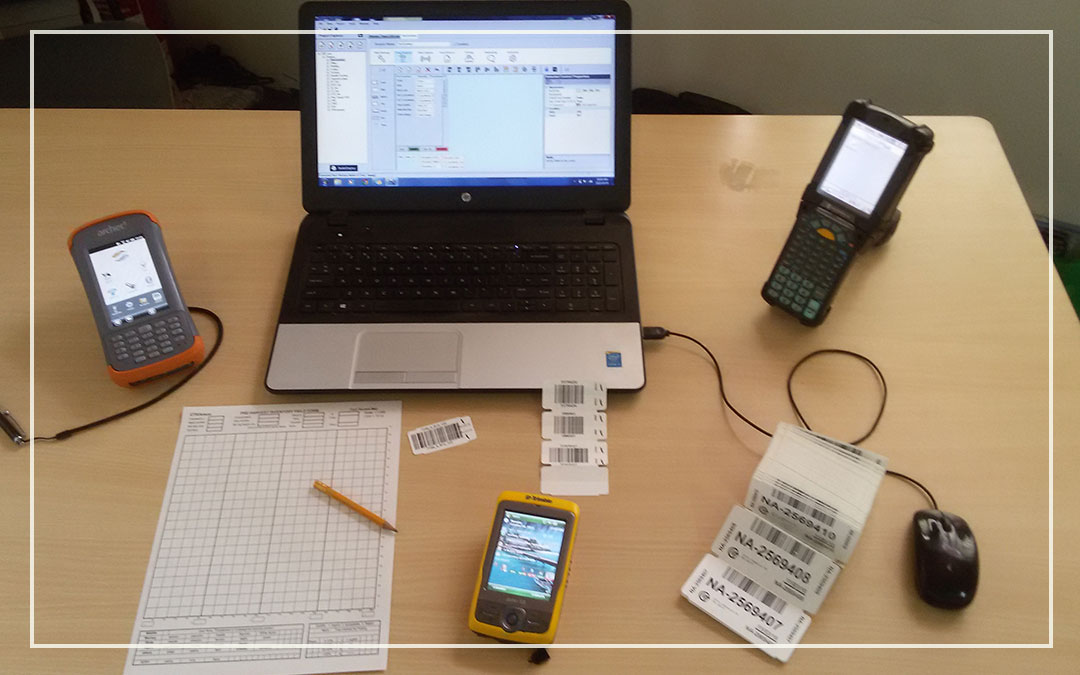

CHAIN OF CUSTODY AND DATABASE ADMINISTRATION

To guarantee this 100% traceability, it is of great importance that all information, from tree to roundwood, via transport to finished sawn product is managed carefully. This is only possible if all data per production and transport phase is documented properly. In Suriname, this is mostly done by means of paper forms, which are then digitally processed by hand. This chain of forms is known as the Chain of Custody. At DBS, we developed a revolutionary system that uses barcodes, handheld PDA’s with barcode scanners, and our own custom developed application that enables us to acquire and process data digitally on location.

Our application, which goes by the name of LoggerPro©, is provided with the necessary data validation mechanisms and subsequent protocols to guarantee that entered information meets the standard for 100% integrity. Because of the fact that the application and the handheld PDA have the user friendliness of a smartphone, everybody can work with it. In this way we are able to realize a fully digital data acquisition for the entire Chain of Custody, from inventory, felling, extraction, scaling, post treatments, transport and sawing. All this data is automatically processed over the internet into our own production database. At this time we re-check the data one last time, to be able to guarantee 100% reliability and legality of our information. Through this, and in combination with all standards for sustainability, we feel comfortable and proud to sell our products as genuinely sustainable Tropical hardwood.